‘Poly’ is short for polypropylene. Polypropylene is a chemical compound, or a plastic. According to Creative Mechanisms, ‘Polypropylene is one of the most commonly produced plastics in the world today.’ It get’s used for many other things like bottles, synthetic fabrics, and plastic bags.

Start From Scratch

According to guichon-valves.com, “Polypropylene is made from the polymerization(chemical reaction) of propylene gas in the presence of a catalyst system. Polymerization conditions (temperature, pressure and reactant concentrations) are set by the polymer grade to be produced.”

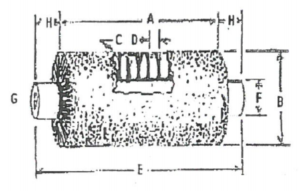

After the raw material is then made into strands and bonded into bunches, it later becomes the bristles of the wafer broom. It is attached to a metal rim that has a small bar so that the ring of the wafer can be fitted onto the machines for sweeping.

Three Kinds

Out of brush types for the wafer, you have flat and convoluted. In a line of them, a flat one must will get placed on the far left and right, and the convoluted are in the middle. The convoluted wafer brushes have the benefit of angled brushing like a zigzag. That can add pick up power to the sweep. The third kind is the angled wafer. This one can serve as a gutter broom and also to pick up from the ground on farms.

Three Material Choices

There are three choices for material in wafer brooms, and each one has its best uses. There are 100% polypropylene, or ‘poly’. These can be best for surfaces that metal would scratch. Runway cleaning would need ‘poly’ as metal fragments could not remain behind on. This material is recyclable as well. 100% metal filament can be best for jobs that need more cutting power and that can take a more abrasive cleaning. The third choice is a mix of both. 50% polypropylene (plastic) bristles and 50% wire bristles. This can be for road resurfacing and construction.