What Are Tube Brooms?

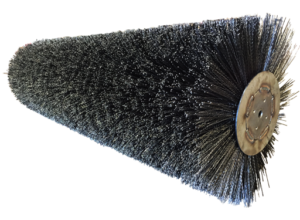

Tube brooms can be on the front, middle, or back of a street sweeping vehicle. They can be made from different materials like Polypropylene, a plastic-like material, steel, or a mix of both. You have probably seen them before when you notice the local street sweeper roll by.

Uses of Tube Brooms

There are many uses for tube brooms. Almost anywhere you would use a street sweeper, a tube broom would make a good fit for the job. Most of our tube brooms are used for street sweeping but there are many other uses.

Other uses:

- Cleaning road construction debris

- Produce cleaning

- Runway maintenance

- Parking lot maintenance

Do you have an idea for a new use? At Smith Equipment, we will be able to help you bring your idea to life.

Who we are

Who we are

Smith Equipment was founded in 1965 by James Smith. We are the southeast leader in the sales and production of industrial brooms. For over 50 years we have been manufacturing all kinds of brooms. We have a wide range of clientele from the U.S. Military, to local businesses maintaining their parking lot.

Did you know we can accommodate international orders? You can enjoy our long-lasting brooms regardless of where your business is! One of the ways our brooms are cheaper without cutting quality is we produce our own polypropylene for our sweeper brooms.

Custom Made Brooms

We can make custom tube brooms to fit your needs. Check out our tube broom selection!

Don’t see what you are looking for? Let us know and we will make it guaranteed!

Ozzie Needs a New Broom

Remember Ozzie? Our lovable giraffe friend at the Lion Habitat Ranch in Las Vegas? For a quick refresher: this giraffe is one of the most popular attractions at the Lion Habitat Ranch. He’s become famous for his works of art he paints for visitors at the ranch. If you remember, Ozzie loves using one of our very own brushes as his scratching post. In fact, he loves using it so much that he’s completely worn the brush down from all his scratching!

Remember Ozzie? Our lovable giraffe friend at the Lion Habitat Ranch in Las Vegas? For a quick refresher: this giraffe is one of the most popular attractions at the Lion Habitat Ranch. He’s become famous for his works of art he paints for visitors at the ranch. If you remember, Ozzie loves using one of our very own brushes as his scratching post. In fact, he loves using it so much that he’s completely worn the brush down from all his scratching!

Just to remind you, our brushes at Smith Equipment aren’t like any ordinary brush. Our brooms are built to withstand copious amounts of pressure for long periods of time. So if he’s already worn down his brush, that really goes to show how much he cherishes his Smith Equipment scratching post!

“What’s better than one brush?” Ozzie says, “two brushes!” Yep that’s right! Since Ozzie wore down his first brush so quickly we’ll be making TWO brooms for our star artist in Vegas so he’ll be able to satisfy all his itches to his heart’s content.

We’re so excited to partner with such a unique customer like Ozzie and his awesome owner Keith. And Ozzie to you we say: may your bristles be straight and your brush be full my friend!

What are Gutter Brooms?

Smith Equipment makes more brooms parts then you would think. Today we will specifically look at the gutter broom. The gutter broom is the one that catches your eye first when the street sweeper rolls by. This is the circular brush that gets into the gutter sending debris inward for collection.

Quality

There is a growing level of competition on gutter brooms. At Smith Equipment, we know that choosing a higher price doesn’t always mean getting a better quality brush. If you were to base your purchasing experience solely off of the price, you might find a product that was less than cost-effective. It’s important to know the basics about gutter brooms when you’re deciding what to purchase.

Blocks

Most gutter broom blocks are Elgin or Mobil. While we stock all major block brands, these two sell more due to their frequency of use. When it comes to gutter broom blocks, there are three distinct types. Wooden Round-tops, wooden blocks, and copolymer blocks make up the bulk of the gutter boom family. The most common form of gutter broom block is the heavy co-polymer block which also highly impacts resistant. These blocks are made to spec. For example, an Elgin gutter broom block has exactly 31 holes and each hole should have 18 steel wires.

The Varieties

The Varieties

In the gutter broom industry, your suppliers should be telling you what kind of steel wire you’re getting. In gutter broom manufacturing, there are two main types of steel wire:

- Oil quenched wire

- Oil tempered wire

Oil quenched steel wire is cold rolled steel that is covered in lubricating oil to help reduce rust and friction. This type of steel wire is cheaper and may wear faster. This is most commonly used for road sweeping. This type of gutter broom wire should never be used for airport maintenance as pieces of the wire left over from sweeping could be embedded or laying on the asphalt.

Oil tempered steel wire is tempered after the forming process which aligns the steel molecules into a lattice. This heating process allows the wire to retain it’s memory and makes it far more resilient. Oil tempered wire is the only steel wire used in sensitive applications like airport maintenance and runway clearing.

Many Kinds

Our gutter brooms are oil quenched steel or oil tempered wire. You can also get gutter brooms in segments and blocks. Still don’t see the one you need? We will make it, guaranteed! Check out our selection.

It’s Hurricane Season! Help Out Your Local Street Sweepers

When hurricanes come around again it is a dangerous time for our environment. Basically, all the trash and litter that is on our yards and roads get washed into the storm drains with the heavy rain. From there, it gets into the water, it makes lakes look dark and murky while also killing our wildlife. One of the most important things a street sweeper does is prevent contamination of our lakes.

Prevention is key!

We have to be careful when we take care of our yard, we can accidentally put the environment at risk! For instance, cutting our grass leaves clippings behind that eventually wash into the drain. You wouldn’t think clippings of grass would be harmful, as we have discussed before when the clippings get into ponds and lakes the excess decomposing grass throws off the aquatic ecosystem and promotes algae growth. Access algae growth consumes the oxygen that the fish need to survive, resulting in much dead fish. This has a direct effect on the production of purifying water for consumption. Use a lawnmower attachment that picks up what you cut. Your yard will look better and the environment will be safer.

Using fertilizers and pesticides have similar effects. Try not to use more than you need, and choose products for your yard that are better for the environment in case some of it does get washed away. Watering your lawn after using a product can help get it to soak into your lawn.

Moving Your Car

Having to park somewhere else can be a hindrance, but it is a huge help for the street sweepers to be able to take care of that area. Street sweepers move very slow and have to skip an area if there is a car blocking it. There are cities like Los Angeles that only have 33% of their streets swept more than once a year. This is largely due to cars not getting moved on scheduled cleaning days. A street sweeper cannot clean an area unless the cars are moved.

Let’s do our part!

So this hurricane season let’s do our part in helping street sweepers be able to do their job effectively. If we take simple measures to make sure our lawn debris, fertilizers, and pesticides are staying out of our lakes and move our vehicles to let street sweepers clean, we can massively impact our local environment this season! And remember, we don’t just do our part during hurricane season – but all year long.

How Often Do You See Your Street Sweepers?

Having to park somewhere else because of street sweepers may be frustrating, but think of it as a good thing. If you live in a place where you always see street sweepers, that means the city cares about staying clean and keeping pollution from its water. Sweeping weekly can be a preventative measure for saving money later. Keeping the streets clean should be a top priority for your city!

Neglected streets of Los Angeles

There are streets in Los Angeles that go a whole year in between cleanings! Can you imagine what that would look like? That has terrible effects on the environment. One-third of Los Angeles gets weekly street cleaning, while the rest does not. This is due to a few different things, but one of the main reasons is that cars have to be off the street for the scheduled street sweepings. If there are cars, then the area has to be skipped, and it’s often skipped until someone complains- “sometimes, less than once a year or when someone complains” said Los Angeles Controller Ron Galperin.

How street sweeping saves money

It can cost the city a lot of money to maintain clean streets as we have talked about with New York, but it is worth it in the long run. It will cost more money to repair things that could have been prevented. For example in storm season, dirt, leaves, and trash get washed into the storm drains with all the rain. Once that debris gets into the storm drains, it then gets into local lakes and pollutes the environment and aquatic life. That polluted water source cannot be used anymore and will be far more costly to restore. Imagine when you see a lake that is murky, and it could have been crystal clear if properly taken care of.

What you can do

The biggest thing you can do is contact your local city government to take street cleaning more seriously (if you do not see weekly street sweeping already). If you manage a property, continue getting routine street cleanings even when it’s the rainy season. Although it is raining and that seems to be keeping things clean, the same stuff is getting into the storm drains. The main reason to have street sweeping is to prevent contaminants from entering the water supply. It is a secondary benefit to have the appearance of well-kept streets.

In your home, if you can collect your grass clippings from getting into the storm drains and use minimal amounts of fertilizers and pesticides that will keep fewer things from getting into the lakes.

A Brief History on Street Sweepers

Street sweepers silently play a huge part in our society. You probably don’t often think of the history of street sweepers, but our quality of life can be determined by many factors like clean water and clean air which are big ones! Street sweepers now use advanced technology to clean our streets and preserve aquatic wildlife, prevent flooding, and keep our breathing air safe. It was not always this way though, it is actually in the recent 30 years that we have become this good with our street sweeping technology.

The first ever street sweeper

According to vacuumcleanerhistory.com, the first street sweeper was not invented until 1843. The patent was named “The Patent Street Sweeping Machine of Manchester” and brought forth by Joseph Whitworth. In America, six years later, C.S. Bishop patented a street sweeping machine. Both of these machines were horse-drawn. There would not be a motorized version for more than sixty years!

It was not until 1911 that John M. Murphy invented a motorized version of the horse-drawn sweeper on paper. Together, the American Tower and the Tank company of Elgin, Illinois were convinced and funded the Elgin Sweeper Company. And after 2 years, the first one was purchased by the City of Boise, Idaho.

When the first street sweeper was needed

The need for a mechanism to clean the streets came after the industrial revolution in the 1840s in Manchester England. This city was known to have been the most developed but also was very trashed. The unhealthiness of the city was from having the first passenger railway service and the largest textile industry in the world at the time. The development was leaving a lot of trash and debris behind and the city needed a way to control this.

The evolution of street sweeping

Street sweepers remained the same until the 1990s and they mainly removed large items. The reasoning was that if the larger things were removed, the rain would take care of the rest. It was not found out until later that the little things are what get into our local water supply through storm drains and contaminate aquatic life.

Now, we have street sweepers that can clean debris so small, that there are some certified to pick things up as small as a micron! That is the size known for some items to get into our lungs. It is thanks to advances in street sweeper technology that we have machines that are highly capable of preventing storm drain pollution. Smith Equipment is one of the companies that make this possible by supplying brooms and accessories for many different kinds of street sweepers. Contact our team for a quote today!

Street Sweeping & Toby’s Water Warriors in Lakeland, FL

Lakeland uses gutter brooms to keep their city clean looking clean and beautiful. The City of Lakeland has over 551 miles of road with curbs. They maintain 6 street sweepers that cover the streets twice every month. In one year, these machines will cover 20,000 miles of the street while picking up 2,500 tons of debris. This is great because that is the stuff that may otherwise end up in our lakes.

How they work

These street sweeping machines have circular brooms in the front, towards the bottom, called gutter brooms. Street sweeping vehicles will drive slowly at the edge of the road brushing the side with these gutter brooms. Most importantly, the debris gets picked up by the main broom, located underneath of the sweeper, and gets stored in the tank of the vehicle.

Toby’s Water Warriors

Do you know Toby?! Toby’s Water Warriors can be seen on all of Lakeland’s street sweepers. The Water Warriors are here to remind Lakeland’s citizens of the dangers of street trash and pollution. Street trash flows into our storm drain and eventually ends up in our lakes. Here are some other harmful pollutants that pose a threat to our water:

- Pet Waste. When possible, pick up pet waste and dispose of it. Rain can take it into the storm drain, and from there it will pollute the lake water.

- Grass Clippings. When grass clippings get into the water, it can cause a nutrient deficiency.

- Fertilizers. Fertilizers can promote algae growth which takes oxygen the aquatic life needs, killing fish.

“Stormwater runoff is now considered the greatest source of pollution to Florida’s lakes, streams, and wetlands. Polluted stormwater runoff has many adverse impacts on surface water quality, aquatic plants and aquatic wildlife.” City of Lakeland

The gutter brooms on your city’s street sweeper are vitally important to the cleanliness of not only your streets but also your lakes and rivers. Call Smith Equipment next time you are in need of quality gutter brooms, tube brooms or wafer brushes. We are here for you and your city!